PRODUCT CENTER

High Dispersion Precipitation Method Silica

Category:

Silica

Summary:

Our company's precipitated white carbon black is mainly divided into two categories: rubber grade white carbon black, green tire specific high dispersion white carbon black, and feed grade white carbon black

Keywords: Special mixed rubber | Modified carbon black | Functional mixed rubber masterbatch | Functional plastic masterbatch

Product Details

High Dispersion Precipitation Method Silica Breed:

Massive: KF-2170

Massive: KF-2170  Micro bead shape: KF-6175MP Highly dispersed microbeads: KF-6165MP

Micro bead shape: KF-6175MP Highly dispersed microbeads: KF-6165MP

High Dispersion Precipitation Method Silica Specification:

Our company's precipitated white carbon black is mainly divided into two categories: rubber grade white carbon black, green tire specific high dispersion white carbon black, and feed grade white carbon black.

High dispersion white carbon black for rubber and green tires

White carbon black for rubber is mainly used in industries such as shoe making, rubber rollers, and tires. Due to its high specific surface area, it has excellent reinforcement performance when applied to rubber products, which can improve the hardness, wear resistance, and tear strength of the products, and extend their service life.

The highly dispersed white carbon black for green tires is a differentiated high-performance product independently developed by our company, which occupies an important position in the domestic and international markets. It can significantly reduce the Rolling resistance of tires and improve the wet skid resistance of tires. It can replace carbon black in a large amount for high-performance tires. While reducing the Rolling resistance of tires, reducing fuel consumption, it can improve the wet skid resistance and steering control safety, and at the same time reduce tire wear, Improved driving safety. Especially in applications such as passenger tyres with low Rolling resistance and winter tyres, its excellent performance is even more obvious. At present, our company produces two major series of silica products for the rubber industry: easily dispersed silica (EDS) and highly dispersed silica (HDS).

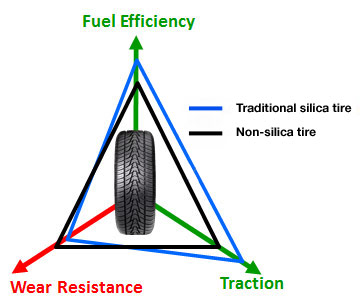

Silicon dioxide products were first used in tire applications, mainly for rubber reinforcement. Since these developments in recent decades, although silica remains the key to rubber reinforcement, the latest generation of highly dispersed silica (HDS) is helping to redefine the "magic triangle" of the tire industry.

、

、

From low surface area materials that improve traction and hysteresis characteristics of winter tires to high surface area materials that improve tread wear and balance Rolling resistance, our company develops new silica materials to meet their specific production and performance requirements.

Silicon dioxide is usually used in combination with silane coupling agents, and practice has shown that tires with added silicon dioxide have the following excellent properties:

Improve wetland traction and fuel efficiency, balance wear resistance

● Enhance the ability to resist cutting, chipping, and tearing

● Promote adhesion to plated steel wire and fabric cords

White carbon black for rubber and high dispersion white carbon black for green tires

|

Product |

Dispersibility |

CTAB Surface Area(m2/g) |

N2 (BET) |

pH |

Salt |

Physical Form |

|

KF-2170 |

EDS is easily dispersed |

N/A |

170 |

7.0 |

≤2.0 |

Granule |

|

KF-6175MP |

EDS is easily dispersed |

160 |

175 |

6.5 |

≤2.0 |

Micro pearl |

|

KF-6165MP |

HDS high dispersion |

160 |

165 |

6.3 |

≤1.5 |

Micro pearl |

High Dispersion Precipitation Method Silica Main Purpose Description

1.KF-2170 Precipitation Method White Carbon Black

(1) Physical and chemical properties

KF-2170 is a high-purity white block precipitated silica with a specific surface area of 170 ± 15m2/g.

(2) Main purpose:

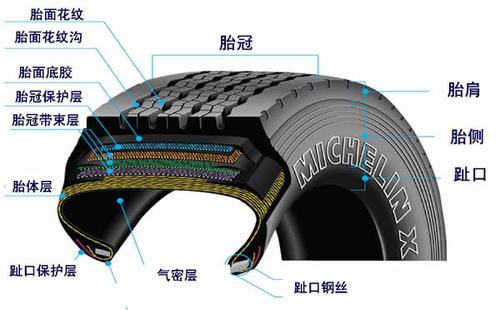

① Used in tire tread, carcass, belt layer, sidewall rubber, and rubber products.

Performance and function:

As a reinforcing filler in rubber, it provides high hardness, high tensile strength, high tear strength, and high wear resistance for rubber formulations, improving the adhesion between rubber and steel cord. Improve the durability of the rubber material, improve its resistance to bending and impact, enhance the traction of the tire on the road surface, and improve tire performance.

② Used for sole materials and rubber products.

2. KF-6175MP Precipitation Method White Carbon Black

(1) Physical and chemical properties

KF-6175MP is a high-purity white micro bead precipitated silica with a specific surface area of 170 ± 15m2/g.

(2) Main purpose:

Used in rubber additives, tire tread, carcass, belt layer, and sidewall rubber.

Performance and function:

As a reinforcing filler in rubber additives, it provides high hardness, high tensile strength, high tear strength, and high wear resistance for rubber additive formulations, improving the adhesion between rubber and steel cord. Improve the durability of the rubber material, improve its resistance to bending and impact, enhance the traction of the tire on the road surface, and improve tire performance.

3.KF-6165MP Precipitation Method White Carbon Black

(1) Physical and chemical properties

KF-6165MP is a high-purity white microsphere like highly dispersed precipitated silica with a specific surface area of 165 ± 10m2/g.

(2) Main purpose:

Mainly used for green tires, it can be used as a rubber additive in tire tread, carcass, belt layer, and sidewall rubber.

Performance and function:

As a reinforcing filler in rubber additives, it provides high hardness, high tensile strength, high tear strength, and high wear resistance for rubber additive formulations, improving the adhesion between rubber and steel cord. Improve the durability of the rubber material, improve its resistance to flexion and impact, enhance the traction of the tire on slippery roads, and improve the all-weather performance of the tire.

Packaging Materials and Specifications:

1. 15kg/bag, 20kg/bag, can be shipped loose, can be stacked into a bracket, coated with film, and then transported.

2. Use 300kg/bag, 400kg/bag, and 600kg/bag packaging.

3. The packaging material is made of PP material and is covered with film to prevent moisture.

4. Packaging can also be carried out according to the packaging form and specifications requested by the customer.

Related products

Phone: +86 153-1889-0084 (ELLA)

E-mail: ella@adalonchem.com

Address: Room 0906, Building 7, Tus Xiexin Technopole, No. 7, Wuyang Road, Shibei District, Qingdao, Shandong, China

Copyright © 2023 Adalon chemical (Qingdao) Co. , Ltd. | SEO | Business license